1. Theoretical Test uye Analysis

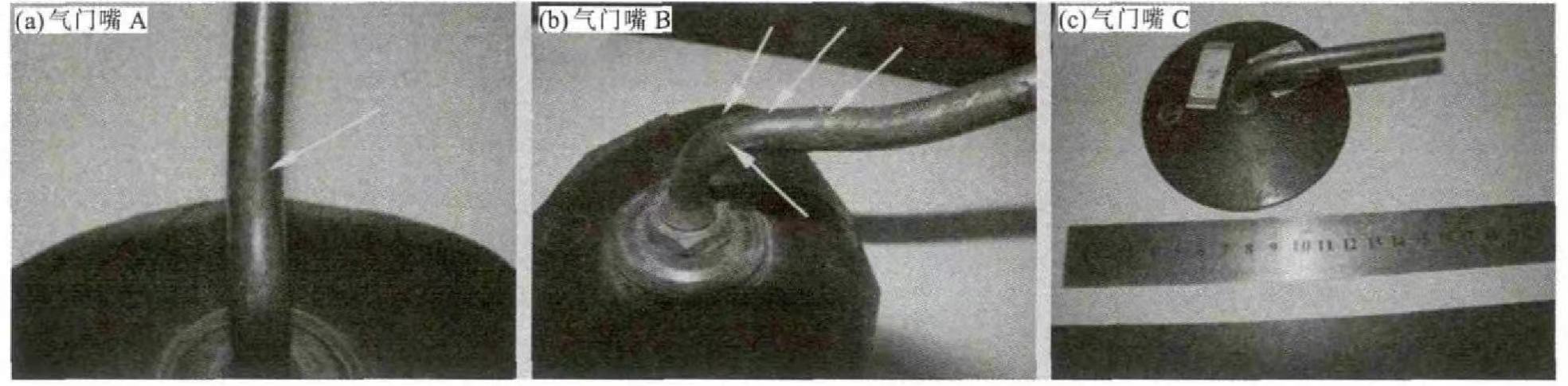

ye3matai mavharuvhusamples dzakapihwa nekambani, 2 mavharuvhu, uye 1 ivharuvhu isati yashandiswa. Kune A uye B, valve isati yashandiswa inotarwa segrey. Comprehensive Figure 1. Iyo yekunze yevharuvhu A haina kudzika, kunze kwevharuvhu B ipamusoro, kunze kwevharuvhu C inzvimbo, uye kunze kwevharuvhu C inzvimbo. Mavharuvhu A uye B akafukidzwa nezvinoita ngura. Ivhavha A uye B inoputika pamabhendi, chikamu chekunze chebhendi chiri pedyo nevhavha, muromo wevhavha yevhavha B inotsemuka kusvika kumagumo, uye museve wakachena pakati penzvimbo dzakaputika pamusoro pevhavha A inotaridzwa. Kubva pamusoro apa, kutsemuka kuri kwese kwese, kwakatsemuka kwakakura, uye kwakatsemuka kuri kwese.

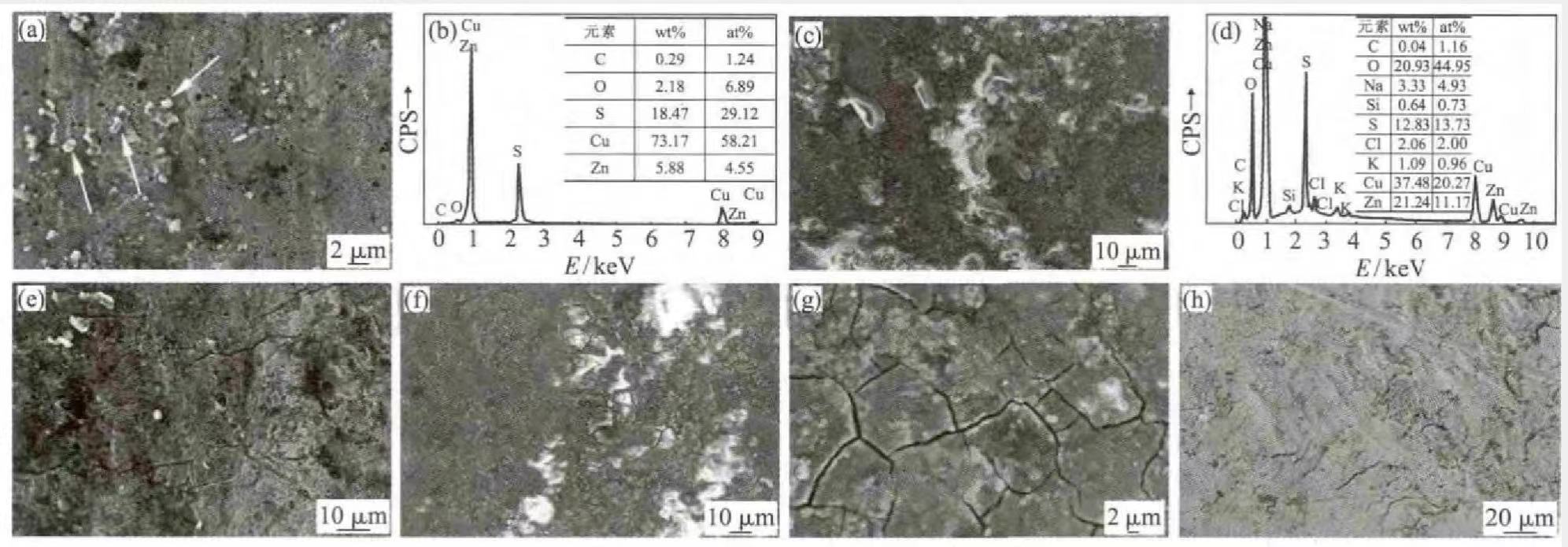

Chikamu chevhiri vhiriA, B, uye C samples akachekwa kubva pakubhenda, uye morphology yepamusoro yakaonekwa neZEISS-SUPRA55 yekuongorora electron maikorosikopu, uye micro-area kuumbwa kwakaongororwa neEDS. Mufananidzo 2 (a) inoratidza microstructure yevhavha B pamusoro. Zvinogona kuonekwa kuti pane zvakawanda zvichena uye zvinopenya zvimedu pamusoro pepamusoro (zvinoratidzwa nemiseve yakachena mumufananidzo), uye EDS kuongororwa kwemavara machena ane huwandu hwepamusoro hweS. Mhedzisiro yemagetsi emagetsi emagetsi emagetsi anoratidzwa mumufananidzo 2 (b).

Mifananidzo 2 (c) uye (e) ndiyo microstructures yepamusoro yevhavha B. Inogona kuonekwa kubva mumufananidzo 2 (c) kuti nzvimbo inenge yakafukidzwa zvachose nemishonga yakasvibiswa, uye zvinhu zvinopisa zvezvigadzirwa zvekuora nemagetsi emagetsi ekuongorora zvinonyanya kusanganisira S, Cl uye O, zvinyorwa zveS mune imwe nzvimbo yakakwirira, uye migumisiro inoratidzwa mumagetsi (drum spectrum). Inogona kuonekwa kubva kuMufananidzo 2 (e) kuti kune micro-cracks pamwe chete nemhete yevharuvhu pamusoro pevhavha A. Mifananidzo 2 (f) uye (g) ndeyepamusoro micro-morphologies yevhavha C, iyo yepamusoro yakafukidzwawo zvachose nemishonga yekuora, uye zvinhu zvinopisa zvinosanganisirawo S, Cl uye O, yakafanana nemufananidzo 2 (e). Chikonzero chekupwanya chinogona kunge chiri stress corrosion cracking (SCC) kubva pakuora chigadzirwa chekuongorora pavharuvhu. Fig. 2 (h) iinewo microstructure yepamusoro yevhavha C. Inogona kuonekwa kuti nzvimbo yacho inenge yakachena, uye makemikari epamusoro akaongororwa neEDS akafanana neyemhangura yemhangura, zvichiratidza kuti valve haina corrod. Nekuenzanisa iyo microscopic morphology uye chimiro chemakemikari ezvitatu zvevharuvhu, zvinoratidzwa kuti kune corrosive media senge S, O uye Cl munzvimbo yakapoteredza.

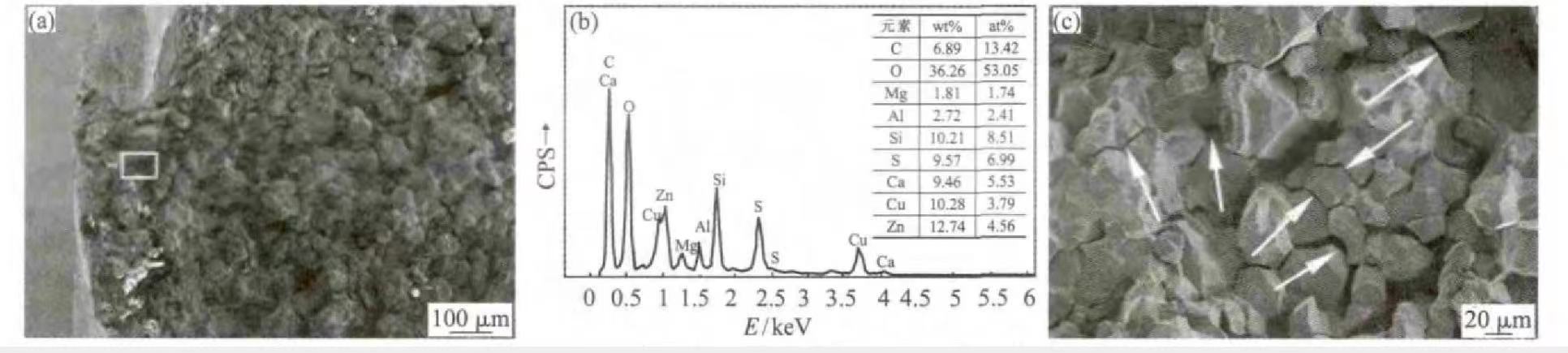

Kutsemuka kwevharuvhu B kwakavhurwa kuburikidza nemuedzo wekukotama, uye zvakaonekwa kuti kuputika hakuna kupinda mukati mechikamu chese chevhavhavha, yakatsemuka padivi rekumashure, uye haina kutsemuka parutivi rwakatarisana neshure kwevhavha. Kuongororwa kwekuona kwekuputsika kunoratidza kuti ruvara rwekuputsika kwakasviba, zvichiratidza kuti kuputika kwave kwakasvibiswa, uye zvimwe zvikamu zvekuputsika zvakasvibirira muvara, izvo zvinoratidza kuti kuparara kwakanyanya muzvikamu izvi. Kutyoka kwevharuvhu B kwakaonekwa pasi pemakorosikopu erekitironi yekuongorora, sezvakaratidzwa muMufananidzo 3. Mufananidzo 3 (a) unoratidza kutaridzika kukuru kwekutsemuka kwevharuvhu B. Zvinogona kuonekwa kuti kunze kwekuputsika pedyo nevhavha yakafukidzwa nezvigadzirwa zvegorosi, zvakare zvichiratidza kuvapo kwehutori hwehuputi munzvimbo yakapoteredza. Maererano nekuongorora kwemagetsi emagetsi, zvikamu zvemakemikari zvechigadzirwa chekuora zvakanyanya S, Cl uye O, uye zviri mukati meS uye O zvakakwirira, sezvinoratidzwa mumufananidzo 3 (b). Kucherekedza nzvimbo yakatyoka, inowanikwa kuti iyo crack growth pattern iri parutivi rwecrystal type. Nhamba huru yekutsemuka kwechipiri inogonawo kuonekwa nekucherechedza kuputsika kwepamusoro-soro, sezvinoratidzwa mumufananidzo 3 (c). Kutsemuka kwechipiri kunoratidzwa nemiseve yakachena mumufananidzo. Zvigadzirwa zveCorrosion uye kuparuka kwekukura mapatani pane yakatyoka pamusoro zvakare inoratidza hunhu hwekushushikana corrosion kuparuka.

Kutyoka kwevharuvhu A hakusati kwavhurwa, bvisa chikamu chevhavha (kusanganisira nzvimbo yakatsemuka), kugaya uye kupurudzira chikamu cheaxial chevhavha, uye shandisa Fe Cl3 (5 g) + HCl (50 mL) + C2H5OH (100 mL) mhinduro yakamiswa, uye metallographic structure uye crack growth morphology yakaonekwa neZepserver Axim. Mufananidzo 4 (a) inoratidza chimiro che metallographic chevhavha, iyo α + β dual-phase structure, uye β inenge yakanaka uye granular uye yakagoverwa pa-α-phase matrix. Mafambiro ekuparadzira mutswe pamitsetse yakatenderedzwa inoratidzwa muMufananidzo 4(a), (b). Sezvo nzvimbo dzakapwanyika dzakazadzwa nezvinogadzirwa necorrosion, mukaha uripo pakati penzvimbo mbiri dzekutsemuka wakapamhama, uye zvakaoma kusiyanisa mapatani ekuparadzira mutswe. bifurcation phenomenon. Kutsemuka kwakawanda kwechipiri (kwakaiswa miseve machena mumufananidzo) kwakacherechedzwawo pamusoro pekutsemuka uku kwekutanga, ona mufananidzo 4 (c), uye aya echipiri akatsemuka akapararira pamwe chete nezviyo. Iyo etched valve sample yakacherechedzwa neSEM, uye yakawanikwa kuti kune akawanda madiki-akatsemuka mune dzimwe nzvimbo dzakafanana nekutsemuka kukuru. Aya madiki-akatsemuka akatanga kubva pamusoro uye akawedzera kusvika mukati mevhavha. Kutsemuka kwacho kwaiva nekaviri uye kwakatambanudzwa pamwe chete nezviyo, ona Mufananidzo 4 (c), (d). Mamiriro ezvinhu uye mamiriro ekushungurudzika kweiyi microcracks inenge yakangofanana neyekutsemuka kukuru, saka inogona kufananidzwa kuti chimiro chikuru chekuparadzira chekuputika chinonziwo intergranular, iyo inosimbiswawo nekuputsika kwekucherechedza kwevhavha B. The bifurcation phenomenon yekuputika zvakare inoratidza maitiro ekushungurudzika kwekuputika kwekuputika kwevhavha.

2. Kuongorora uye Kukurukurirana

Kupfupisa, zvinogona kutaurwa kuti kukuvadzwa kwevhavha kunokonzerwa nekushungurudzika corrosion kuputika kunokonzerwa neSO2. Stress corrosion cracking inowanzoda kusangana nemamiriro matatu: (1) zvinhu zvinonzwa nekuora mwoyo; (2) corrosive medium inonzwa kune alloys emhangura; (3) mamwe mamiriro ekushushikana.

Zvinowanzotendwa kuti simbi dzakachena hadzitamburi nekuora kwekushushikana, uye maalloys ese anogona kukonzeresa corrosion kune madhigirii akasiyana. Zvemidziyo yendarira, zvinowanzo davirwa kuti iyo mbiri-chikamu chimiro chine yakanyanya kushushikana corrosion susceptibility pane imwechete-chikamu chimiro. Zvave zvichishumwa mumabhuku kuti kana Zn zviri mumhangura inodarika 20%, ine yakanyanya kushungurudza corrosion susceptibility, uye iyo yakakwirira yeZn yezvinyorwa, iyo inowedzera kushushikana kwekuora mwoyo. Iyo metallographic chimiro chegasi nozzle mune iyi kesi ndeye α + β dual-phase alloy, uye iyo Zn yemukati inenge 35%, inopfuura kure 20%, saka ine yakanyanya kushushikana corrosion senitivity uye inosangana nemamiriro ezvinhu anodiwa pakushungurudzika corrosion cracking.

Zvemidziyo yendarira, kana kusagadzikana kwekugadzirisa annealing kukasaitwa mushure mekutonhora kwekushanda deformation, kusagadzikana ngura kuchaitika pasi pemamiriro akakodzera ekushushikana uye nharaunda dzinoparadza. Kushushikana kunokonzera kushushikana kuora kutsemuka kunowanzo kushushikana kwenzvimbo, uko kunogona kuiswa kushushikana kana kusara kushushikana. Mushure mekunge vhiri rerori rakwidziridzwa, kushushikana kwekunetseka kunogadzirwa pamwe neaxial kutungamira kwemhepo muromo nekuda kwekumanikidza kwakanyanya muvhiri, izvo zvinokonzeresa kutsemuka kwemhepo mumhepo. Kushungurudzika kunokonzerwa nekumanikidzwa kwemukati kwetairi kunogona kuverengwa chete maererano ne σ = p R / 2t (apo p inopinda mukati mukati mevhiri, R ndiyo dhayamita yemukati yevhavha, uye t ndiyo rusvingo rwevhavha). Zvisinei, kazhinji, kushushikana kunokonzerwa nekumanikidzwa kwemukati kwetai hakusi kwakanyanya, uye mhedzisiro yekusarira kunetseka kunofanirwa kutariswa. Nzvimbo dzekutsemuka dzemagasi egasi ese ari kumashure, uye zviri pachena kuti yakasara deformation kubackbend yakakura, uye kune yasara tensile stress ipapo. Muchokwadi, mune zvakawanda zvinoshanda zvemhangura alloy components, stress corrosion cracking haiwanzokonzerwi nedhizaini yekugadzira, uye mazhinji acho anokonzerwa nekusarira kunetseka kusingaonekwe uye kufuratirwa. Muchiitiko ichi, kumusana webhendi yevhavha, kutungamirirwa kwekutambudzika kunokonzerwa nekumanikidzwa kwemukati kwetairi kunopindirana nehutungamiri hwekushungurudzika kwakasara, uye kukwidziridzwa kwezvinhu zviviri izvi zvinopa kushushikana kwehutano hweSCC.

3. Mhedziso uye Mazano

Mhedziso:

Kutsemuka kwevhiri vhirikunonyanya kukonzerwa nekushungurudzika corrosion cracking inokonzerwa neSO2.

Suggestion

(1) Tsvaga kwakabva svikiro rinoparadza munzvimbo yakapoteredzavhiri vhiri, uye edza kudzivirira kusangana zvakananga neyakakomberedza corrosive medium. Semuenzaniso, chigadziko chekudzivirira-corrosion coating chinogona kushandiswa pamusoro pevhavha.

(2) Iyo yakasara yekumanikidza kushushikana kwekushanda kunotonhora inogona kubviswa nemaitiro akakodzera, senge kushushikana kudzikamisa annealing mushure mekukotama.

Nguva yekutumira: Sep-23-2022