Hurukuro Yakadzama pane Dhizaini uye Tsvagiridzo yeIntelligent Valve Core Assembly System

Nhanganyaya

Sezvo hurongwa hwegungano iri mutsara wekugadzira uye yakangwara yekugadzira unit, nekuenderera mberi kwekuvandudza kwehungwaru kutonga tekinoroji uye yakanatswa kugadzirisa, dhigirii rayo re automation rinoramba richiwedzera.Finish.Iyo valve core control intelligent assembly system yakagadzirirwa mubepa rino inoziva iyo yakakosha automation yekusarudza zvinhu uye kukiya vharafu, uye zvigadzirwa zvakakanganisika zvinosanganiswa neiyo yekuona sisitimu yekugadzirisa gungano.Adopt PLC uye yemunhu-muchina interface kuita sisitimu, uye chimiro chemuchina chakagadzirwa uye chine musoro.Kupedzwa kwekugadzirwa kwegadziriro iyi kunovandudza zvikuru kubudirira kwekugadzirwa kweiyo valve coreyakasungirirwa pavhavha, uye inopa muenzaniso wekuvakwa kwemhando iyi yehurongwa.

Nekukurumidza kuwedzera kwenhamba yezvikamu zvevharuvhu, mhepo yemhepo inoramba ichiwedzera, iyo ndiyo dhigirii iyo motokari inotyaira motokari iri pamusuwo, uye nheyo yemotokari pamusuwo inowedzera uye yakawanda, uye musuo haugoni kuvharwa.Mumwe anogona kuona hungwaru hwekuona basa Iyo ine hungwaru module inogona kuona dambudziko rakangwara pane yakangwara module [1].Kuvandudza kushanda kwekugadzira uye chiyero chakanaka.

1. Kuomerwa kwekuongorora kwevhavha core uye maitiro ayo ekusangana

Muchidzidzo ichi, mushure mekutora ruzivo rwekugadzira mamwe maitiro ekugadzirisa otomatiki, iyo iripo semi-otomatiki musangano system yakaongororwa, uye chikamu chemuchina chegadziriro yacho chakanyatsogadzirwa zvichibva pakuenzanisa kweiyo valve core assembly process.Muchirongwa chedhizaini yehurongwa, tinoyedza kuita kuti kugadzirisa kwemekiniki zvikamu zvive nyore, kuderedza mutengo, kuita kuti kuungana kwezvikamu kuve nyore uye kuve nyore, uye kuita kuti sisitimu ive nehumwe dhigirii rekuvhurika uye kuwedzera, kuitira kusimudzira kuvimbika. uye kushanda zvakanaka kwehurongwa., uye kuisa hwaro hwakanaka hwekuvandudza mutengo wekuita kwehurongwa.

Iyo valve core assembly systeminonyanya kukamurwa kuita zvikamu zvitatu maererano nemagadzirirwo ayo emuchina, zvinoti: zvikamu zviviri zvegungano pakona yekumusoro kuruboshwe yebhenji rebasa, zvikamu zvitatu zvegungano pakona rezasi rekuruboshwe uye zvikamu zvinomwe zvegungano kurudyi rwechikamu chebhenji.Iko kuoma kwehunyanzvi hwegungano rezvikamu zviviri kuri munzira yekuita denderedzwa chimiro chemhete yekuisa chisimbiso.Munguva yekucheka, ichaiswa pasi peaxial extrusion simba reblade, saka zviri nyore kukanganisa.Chechipiri, panguva yegungano, kana cored tsvimbo yaonekwa pane yekufambisa tooling chikamu, zvinodikanwa kuti uone kuongorora uye kuungana pakati pezvikamu zvakasiyana zvemusimboti wegonhi kuburikidza nekudengenyeka.Naizvozvo, chikamu chimwe nechimwe chinowira munzvimbo inoenderana kuti ive chinongedzo chegungano.Iyo nzira yakaoma iri mu.Matambudziko ari pamusoro apa ndiwo zvikonzero zvikuru zvekuwedzera kweiyo yakaremara chigadzirwa chiyero muvharuvhu core assembly panguva ino.Zvichienderana neizvi, bepa iri rinogonesa maitiro evhavha musimboti musangano, uye rinowedzera yemhando yekuongorora system yekuvandudza chiyero chekufanirwa kwevhavha core assembly.

2. Intelligent system dhizaini yevharuvhu core pamuromo wevharuvhu

-

2.1Intelligent valve core assembly scheme design

Iyo yekushanda interface uye iyo PLC inoumba logic control chikamu, uye iyo yekuona system uye PLC ine nzira mbiri dzekuyerera kweruzivo kuunganidza iyo mamiriro data yegungano system uye kuburitsa chiratidzo chekudzora.Sechikamu chekutonga, iyo drive system inodzorwa zvakananga neiyo PLC inobuda chikamu.Kunze kwehurongwa hwekudyisa, hunoda rubatsiro rwemanyorero, mamwe maitiro muhurongwa uhu aona gungano rakangwara.Kudyidzana kwakanaka kwevanhu-kombuta kunowanikwa kuburikidza nekubata skrini.Tichifunga nezvekureruka kwekushanda mune dhizaini dhizaini, iro gonhi repakati pekuisa bhokisi riri padyo neiyo touch screen.Muchina wekuona, gonhi repakati-kuvhurika kumusoro-kuvhuvhuta chikamu, iyo yevhavha yepakati kureba yekuona chikamu uye blanking mechanism yakarongedzerwa yakatenderedza turntable tooling chikamu, ichiona dhizaini yekugadzira mutsara wemusuwo wepakati musangano.Iyo yekuona sisitimu inonyanya kupedzisa core tsvimbo yekuona, yekuisa kureba yekuona, yemhando yekuongorora, nezvimwewo, iyo isingango ziva otomatiki yekusarudzwa kwezvinhu uye valve core lock, asi zvakare inovimbisa kugadzikana uye kushanda kwakanyanya kwegungano.Chimiro chechikamu chimwe nechimwe chegadziriro chinoratidzwa mumufananidzo unotevera.

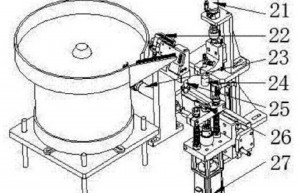

Sezvinoratidzwa muMufananidzo 1, turntable ndiyo yepakati yekubatanidza kwese kuyerera kwemaitiro, uye kuungana kwepakati pevhavha inopedzwa nekutyaira kweiyo turntable.Kana iyo yechipiri yekuongorora nzira inoona chikamu kuti chiunganidzwe, inotumira chiratidzo kune iyo control system, uye iyo control system inoronga basa reimwe neimwe process unit.Kutanga, iyo vibrating disc inozunungusa musimboti wegonhi uye woikiya mumuromo wevharuvhu yekupinda.Yekutanga yekuona michina ichanyatso tarisa mavharuvhu cores asina kunyatsoiswa seakaipa zvinhu.Chikamu 6 chinoona kana mhepo yevheji yevhavha inokodzera, uye chikamu 7 chinoona kana kureba kwekuiswa kwevhavha yepakati kunosangana nechiyero.Zvigadzirwa chete zvinokwanisa mumatanho matatu ari pamusoro ndizvo zvinotorwa mubhokisi rezvigadzirwa zvakanaka, zvikasadaro zvinozobatwa sezvigadzirwa zvine hurema.

2.2 Dhizaini yezvikamu zvakakosha zvevhavha core assembly system

Sezvo nzira yakakosha yekuisa simbi yevhavha pavhavhavha, kukiya vheji yevhavha ine zvakanyanya zvakanyanya zvinodiwa pakurongeka kwenzvimbo yekufamba kwepakati pevhavha, saka inoda kurongeka kweiyo longitudinal uye lateral nzira kuti ipedze.Mumagadzirirwo echikamu ichi, inoodzwa kuita chimwe chiito, kuburitsa kwevhavha core, kukiya chiito chevhavha yekuvhara uye chiito chekuisa simbi yevhavha pavharuvhu.Iyo mechanical chimiro inoratidzwa mumufananidzo 2.

Sezvinoonekwa kubva kuMufananidzo 2, iyo mechanic chimiro chevhavha yepakati musangano yakakamurwa kuita zvikamu zvitatu.Zvikamu zvitatu zvinoshanda zvakabatana pasina kukanganisa mumwe nemumwe.Kana chiito chekuzvimiririra chapera, silinda inosundidzira nzira yekuenda kune imwe nzvimbo yegungano inotevera.Kuti uone kurongeka kwenzvimbo inofamba, iyo yakazara dhizaini yekutonga kwemagetsi uye mechanical muganho inogamuchirwa kudzora kukanganisa mukati me1.4mm.Iyo yepakati yevharuvhu uye yepakati yevhavha nozzle ndeye coaxial, kuitira kuti servo mota ikwanise kusundira musimboti wevharuvhu muvharuvhu nozzle zvakanaka, zvikasadaro zvinokonzeresa kukuvadza kune zvikamu.

Kumira kwechigadzirwa chemuchina kana kusajairika kupuruzira kwemasaini emagetsi kunogona kukonzera kutsauka kudiki mubasa regungano.Somugumisiro, mushure mokunge nheyo yevhavha yakaunganidzwa, kushanda kweventilation hakusi kusvika kuhutano, uye urefu hwegungano hauna kukodzera, izvo zvinotungamirira kukukundikana kwechigadzirwa.Ichi chinhu chinotariswa zvizere mudhizaini dhizaini, kuvhuvhuta kwemhepo uye kuona kureba kunoshandiswa kugadzirisa zvakaipa zvigadzirwa.

2.3 Dhizaini yevhavha core assembly control system

Iyo yekudzora sisitimu mudhizaini iyi inonyanya kusanganisira PLC logic control, servo mota drive system, yekuona system uye HMI man-muchina interface.Iyo servo drive system inonyanya kuumbwa ne servo mota, inoderedza, nezvimwewo, inotyaira zvikamu zvemakanika kufamba mushure mekugamuchira chiratidzo.Iyo servo system inogona kuona chaiyo chinzvimbo uye kukurumidza kugadzirisa pasi pekutonga kwePLC.Iyo yekuona sisitimu inosanganisira mafotoelectric sensors, light sensors, laser sensors, nezvimwe, izvo zvinonyanya kuona mabasa ekuona kwekuisa, kuona zvikamu uye kuzivikanwa, uye maitiro ekutevedzana kwekuenzanisa.HIM murume-muchina interface inotora graphical programming module, iyo inogona kuona yakanaka man-muchina kupindirana.Mushandi anogona kudzora zvakananga sisitimu kuburikidza neanoshanda interface, uye maitiro egungano uye paramita anogona zvakare kuratidzwa zvakananga kuburikidza neiyo interface.

Iyo sisitimu inogona kusarudza yemanyorero musangano modhi uye otomatiki gungano modhi kuburikidza neyekushanda interface.Mune otomatiki modhi, iyo sisitimu inoungana otomatiki zvinoenderana nekuita kwegungano.Mune manyorero ekushandisa modhi, iyo sisitimu inomhanya mune imwe nhanho, uye yega yega chiito chekushanda hachizoenderera mberi.Kuitwa kwechirongwa chehurongwa kunotanga kubva kune-sub-network yekutenderera inotenderera, iyo PLC inoburitsa yekudzora chiratidzo chekutonga, uye servo mota inotyaira kurodha uye kutenderera kwedhisiki.Kana iyo turntable inotakura iyo yevhavha yepakati kune inoenderana tekinoroji process chinzvimbo, iyo tekinoroji process subroutine inomhanya, uye chikamu chekuuraya chinoita chinoenderana chiitiko zvinoenderana nechiratidzo chekudzora.

3. Kuguma

The process flow of valve core installation onvharafuhaisi yakaoma, asi zvinodiwa pakunatswa kwemaitiro acho zvakanyanyisa.Naizvozvo, gungano remanyorero uye semi-otomatiki gungano rinonyanya kushandiswa mukugadzirwa kwemaindasitiri, uye kuita kwavo uye mhando haina kugadzikana.Mune bepa rino, yakangwara yekusangana system yevhavha yepakati yakaiswa pavharuvhu yakagadzirwa, iyo inoona otomatiki yekusarudzwa kwezvinhu uye kuvhara kwevhavha yepakati, uye inoona kushanda kwemhepo uye kukwirisa kweiyo valve core assembly kuburikidza neiyo yekuona system, uye maonerwo ezvawanikwa anozozvikwidzira otomatiki kune yekudzora sisitimu kuti uone otomatiki kuronga kwezvinhu zvakakanganisika.Kushanda kwekushanda uye kugadzikana kwechigadzirwa chevhavha yevhavha yakaiswa pavhavha nozzle inovandudzwa.

Nyora meseji yako pano ugotitumira